Our New Yxlon UX-50 Scanner Scanning Improves Casting Confidence

By Evan Miller, Design Engineer — Kimura Foundry America

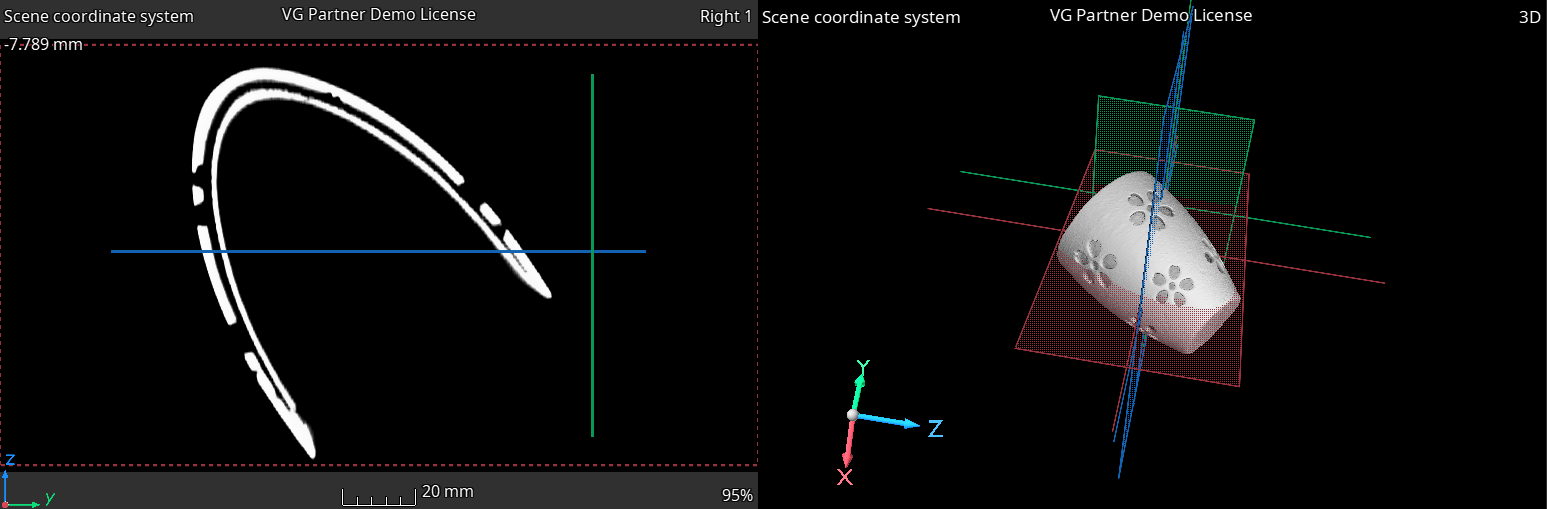

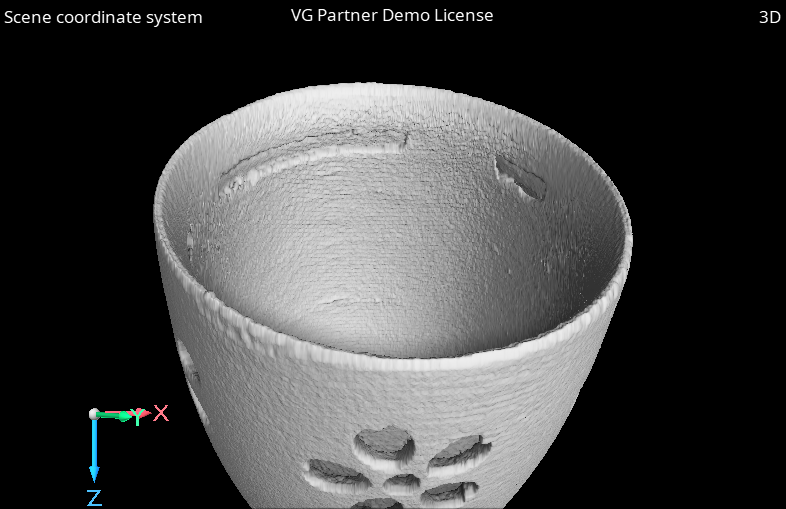

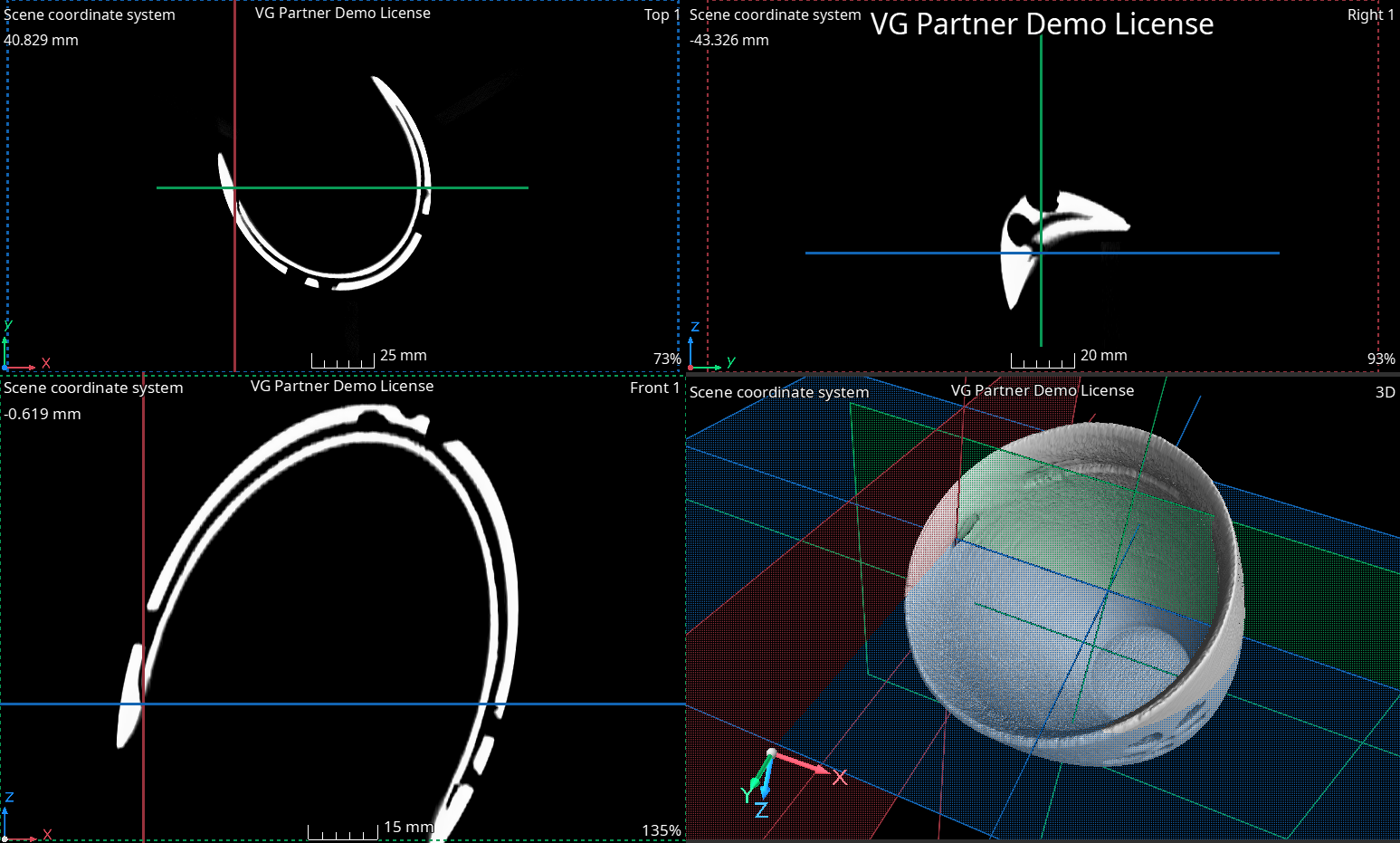

The engineering team is excited about the recent acquisition of our upgraded CT scanner, the Yxlon UX-50. This new system represents a major step forward in how quickly we can validate internal soundness in castings — and that speed ultimately helps our customers move from design to production with more confidence.

The UX-50 significantly reduces the time it takes to scan aluminum parts, even allowing for live scanning in some cases. Previously, achieving the resolution needed to detect microporosity could take nearly a full day. Now, we can identify porosity under 1 mm in about 15 minutes. For iron and steel parts, where density creates more resistance, we are still seeing a 60% reduction in scan time.

Faster CT feedback means we can spot potential issues much earlier, before they turn into costly delays. Because our engineering team leads the quoting process, having rapid, in-house validation helps us avoid charging customers a premium and eliminates up to a week of additional lead time. The result is faster collaboration, quicker design iteration, and greater confidence in the soundness of each casting.

We’re already putting the UX-50 to work, and look forward to sharing more scan examples and deeper insights as we continue rolling out this capability.